What Is a Bellows Sealed Gate Valve?

Introduction

When you operate steam, high-temperature, or hazardous fluid systems, valve leakage can lead to safety risks, energy loss, and costly downtime. Bellows sealed gate valves are designed specifically to eliminate stem leakage while delivering long-term reliability. Understanding how they work helps you choose safer, more efficient flow control solutions.

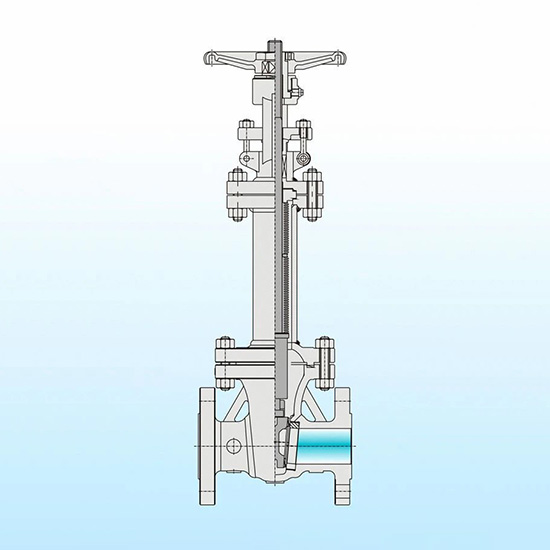

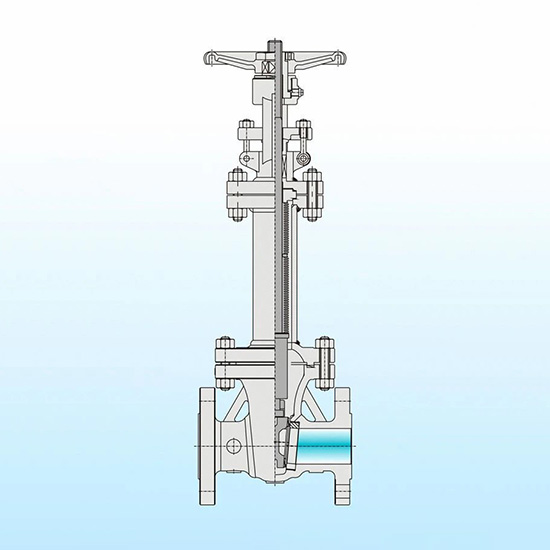

What Is a Bellows Sealed Gate Valve and How Does It Differ From a Standard Gate Valve?

A bellows sealed gate valve is a type of industrial valve that uses a flexible metal bellows to completely seal the valve stem from the process fluid. Unlike standard gate valves that rely on packing seals, bellows sealed valves prevent leakage through a welded metal barrier.

Main Differences:

|

Feature

|

Bellows Sealed Gate Valve

|

Standard Gate Valve

|

|

Stem sealing

|

Metal bellows + packing

|

Packing only

|

|

Leakage risk

|

Nearly zero

|

Possible over time

|

|

Safety

|

Very high

|

Moderate

|

|

Maintenance

|

Lower

|

Higher

|

If you need leak-proof performance, bellows sealed designs provide a major upgrade.

How Bellows Sealed Gate Valves Work

The bellows is a thin-walled, accordion-shaped metal tube welded to both the valve stem and bonnet.

When you open or close the valve:

- The bellows expands or contracts with stem movement

- The fluid is completely isolated from the stem area

- No media escapes through the packing zone

Most designs also include a double sealing system — bellows plus traditional packing — for extra safety.

Key Components and Material Considerations

Metal Bellows (Usually Stainless Steel)

Provides flexibility, corrosion resistance, and high-temperature strength.

Valve Body

Often carbon steel, alloy steel, or stainless steel depending on pressure and media.

Gate and Seat

Designed for tight shut-off and long service life.

Bonnet Assembly

Supports bellows movement and pressure containment.

High-quality materials directly affect durability and leak prevention.

Advantages of Bellows Sealed Gate Valves

- Complete stem leakage prevention

- Ideal for steam and hazardous fluids

- Long service life

- Reduced maintenance costs

- Improved workplace safety

- Excellent performance under high temperature and pressure

You gain both operational reliability and environmental protection.

Applications of Bellows Sealed Gate Valves

- Steam systems and boilers

- Chemical processing plants

- Oil and gas facilities

- Power generation

- Corrosive and toxic media pipelines

- High-temperature industrial processes

Any system where leakage is unacceptable benefits from bellows sealing technology.

How to Choose the Right Bellows Sealed Gate Valve

Selecting the right bellows sealed gate valve ensures long-term safety, efficiency, and low maintenance in your industrial system. Instead of choosing only by size or price, you should evaluate several technical factors that directly impact performance.

Operating Pressure and Temperature

Always match the valve’s pressure class and temperature rating with your system conditions.

- High-pressure steam requires reinforced valve bodies and thicker bellows

- High-temperature environments demand stainless steel or alloy bellows

Choosing an underrated valve can lead to early failure or leakage.

Media Type and Corrosion Resistance

Different fluids affect valve materials differently.

You should consider:

- Steam and hot water → stainless steel bellows preferred

- Corrosive chemicals → corrosion-resistant alloys

- Oil and gas → high-strength steel bodies

Material compatibility directly determines service life.

Bellows Design and Sealing Structure

Not all bellows are equal.

Look for:

- Multi-layer stainless steel bellows for durability

- Fully welded bellows for zero leakage

- Double sealing systems (bellows + packing) for added safety

This structure ensures long-term leak prevention.

Valve Size and Connection Type

Choose according to pipeline layout:

- Flanged connections for high-pressure industrial lines

- Butt-weld ends for permanent installations

- Threaded connections for smaller systems

Correct sizing avoids pressure loss and flow restriction.

Compliance With Industry Standards

Reliable valves typically meet standards such as:

Certification ensures performance under real operating conditions.

Maintenance Best Practices

- Inspect bellows integrity regularly

- Monitor for abnormal stem resistance

- Keep valves clean from debris buildup

- Follow proper operating procedures

- Replace packing if backup seal shows wear

With proper care, bellows sealed valves deliver years of reliable service.

(All images are sourced from the internet. In the event of any copyright infringement, please contact us and we will remove the content promptly.)

FAQs

Q: What is the purpose of a bellows sealed gate valve?

To prevent stem leakage and ensure leak-proof operation in demanding industrial environments.

Q: Why are bellows sealed valves used in steam systems?

They withstand high temperatures while eliminating dangerous steam leakage.

Q: How does a bellows sealed valve prevent leakage?

A welded metal bellows creates a physical barrier between fluid and stem movement.

Q: When should you use a bellows sealed gate valve?

For high-temperature, corrosive, toxic, or safety-critical applications.

Q: Are bellows sealed valves more durable than standard valves?

Yes, they typically offer longer service life with lower maintenance needs.

Conclusion

If you need absolute leak prevention in high-temperature or hazardous systems, bellows sealed gate valves are one of the safest and most reliable solutions available. Their metal sealing technology, durability, and low maintenance make them ideal for critical industrial applications. With FULL-THINK bellows sealed gate valves, you secure performance, safety, and long-term operational confidence.

1